Introduction:

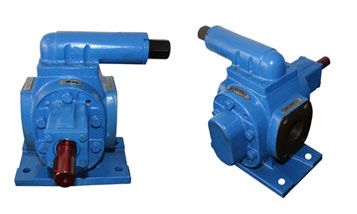

Rotary gear pumps are a type of positive displacement pump that are widely used in various industries for transferring fluids such as oils, fuels, and chemicals. These pumps are known for their high efficiency, smooth operation, and ability to handle a wide range of viscosities. In this article, we will discuss the working principle, types, and applications of rotary gear pumps.

Working Principle:

The working principle of a rotary gear pump is based on the meshing of two gears rotating in opposite directions. The fluid enters the pump through the inlet and fills the spaces between the gear teeth. As the gears rotate, the fluid is carried along the outer periphery of the gears and is discharged through the outlet. The tight tolerances between the gears and the pump casing prevent any leakage and ensure a constant flow of fluid.

Types of Rotary Gear Pumps:

There are two main types of rotary gear pumps: external gear pumps and internal gear pumps.

External Gear Pumps:

External gear pumps have two identical gears that rotate in opposite directions. The fluid is drawn into the pump between the teeth of the gears and is carried around the outside of the gears to the discharge port. External gear pumps are commonly used for low to medium viscosity fluids.

Internal Gear Pumps:

Internal gear pumps have one external gear and one internal gear. The fluid enters the pump through the inlet and is trapped between the external gear and the internal gear. As the gears rotate, the fluid is carried along the outer periphery of the internal gear and is discharged through the outlet. Internal gear pumps are commonly used for high viscosity fluids.

Applications of Rotary Gear Pumps:

Rotary gear pumps are used in a wide range of applications such as:

Chemical processing: Rotary gear pumps are commonly used for transferring chemicals such as acids, solvents, and resins.

Oil and gas industry: Rotary gear pumps are used for transferring oils, fuels, and lubricants in the oil and gas industry.

Food and beverage industry: Rotary gear pumps are used for transferring fluids such as fruit juices, beer, and wine in the food and beverage industry.

Transportation industry: Rotary gear pumps are used for transferring fluids such as diesel and gasoline in vehicles.

Conclusion:

Rotary gear pumps are an efficient and reliable option for fluid transfer in various industries. They come in different material of constructions such as CI, CS, SS to suit different fluid viscosities and Ph. Values. External gear pump are known for their smooth and quiet operation. Whether you need to transfer low viscosity fluids or high viscosity fluids, a rotary gear pump can be a great choice for your application.