-

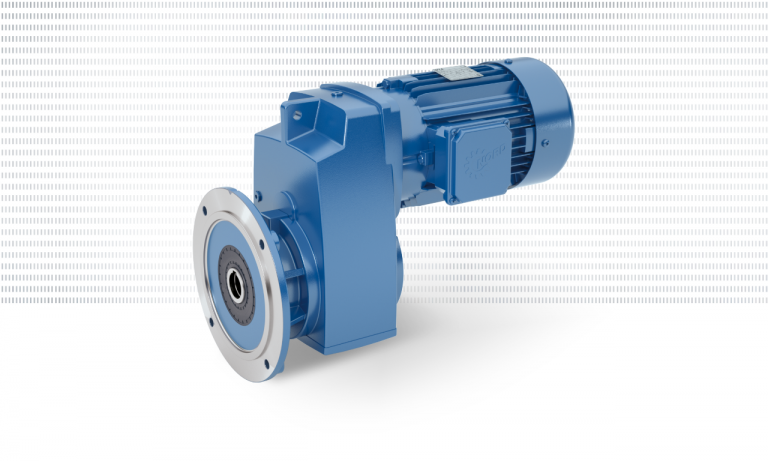

Inline Helical Gearbox & Helical Geared MotorInline Helical Gearbox & Helical Geared Motor

-

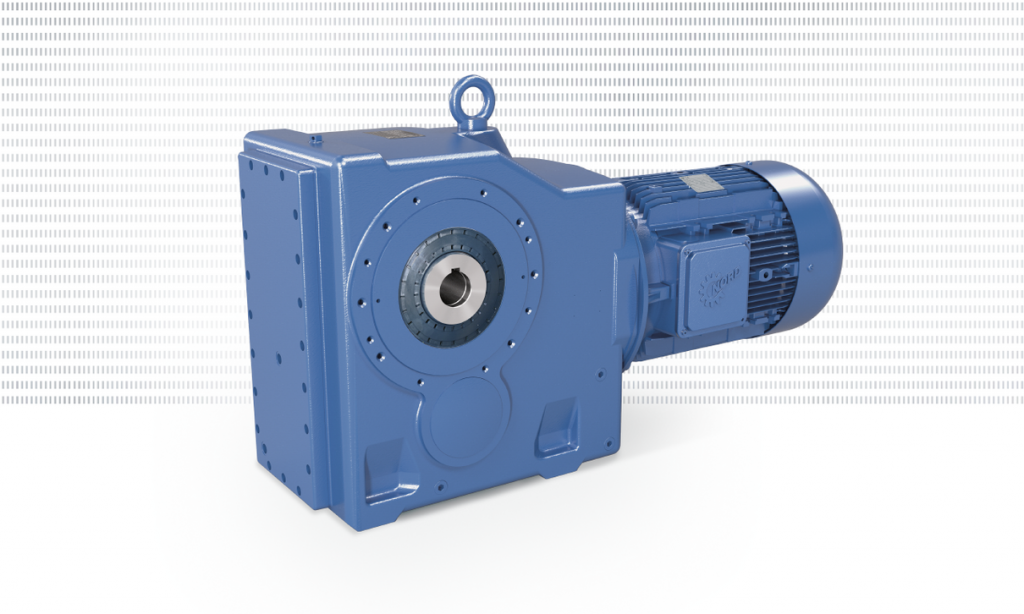

Parallel Shaft Geared MotorParallel Shaft Geared Motor

-

Bevel Helical Gearbox & Helical Bevel Gearbox for Industrial UseBevel Helical Gearbox & Helical Bevel Gearbox for Industrial Use

-

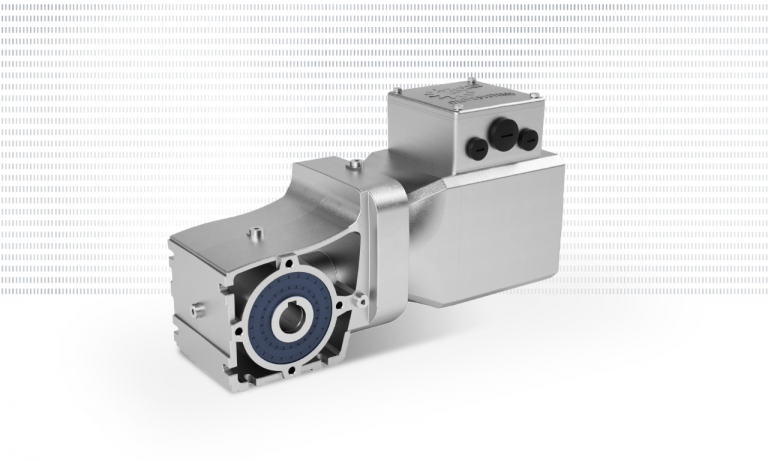

Bevel Helical Geared MotorBevel Helical Geared Motor

-

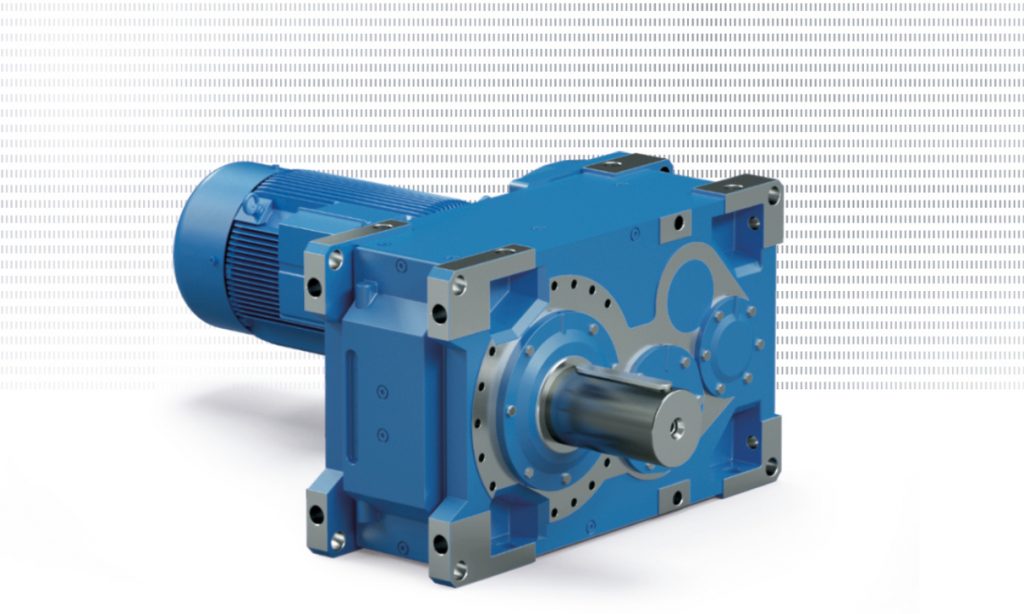

Maxxdrive Right-Angle Gear UnitsMaxxdrive Right-Angle Gear Units

-

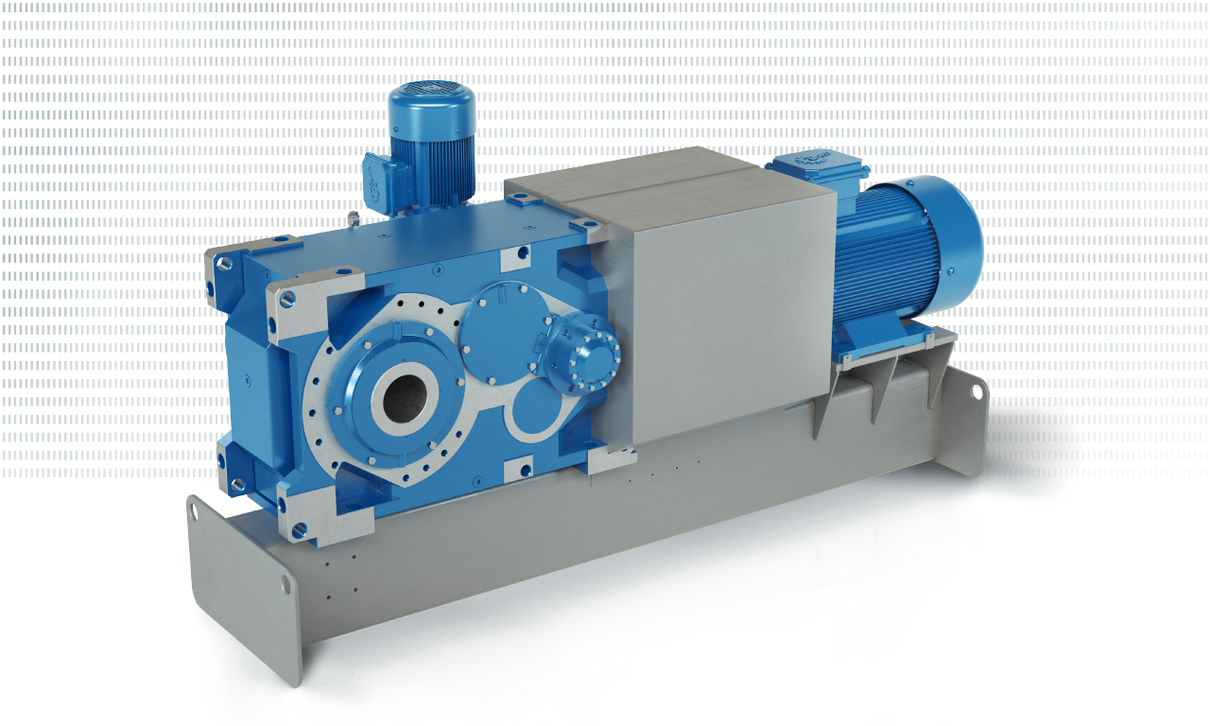

Maxxdrive Parallel Gear UnitsMaxxdrive Parallel Gear Units

-

Worm Geared MotorWorm Geared Motor

-

Universal SI Worm Geared MotorUniversal SI Worm Geared Motor

-

Universal SMI Worm Geared MotorUniversal SMI Worm Geared Motor

-

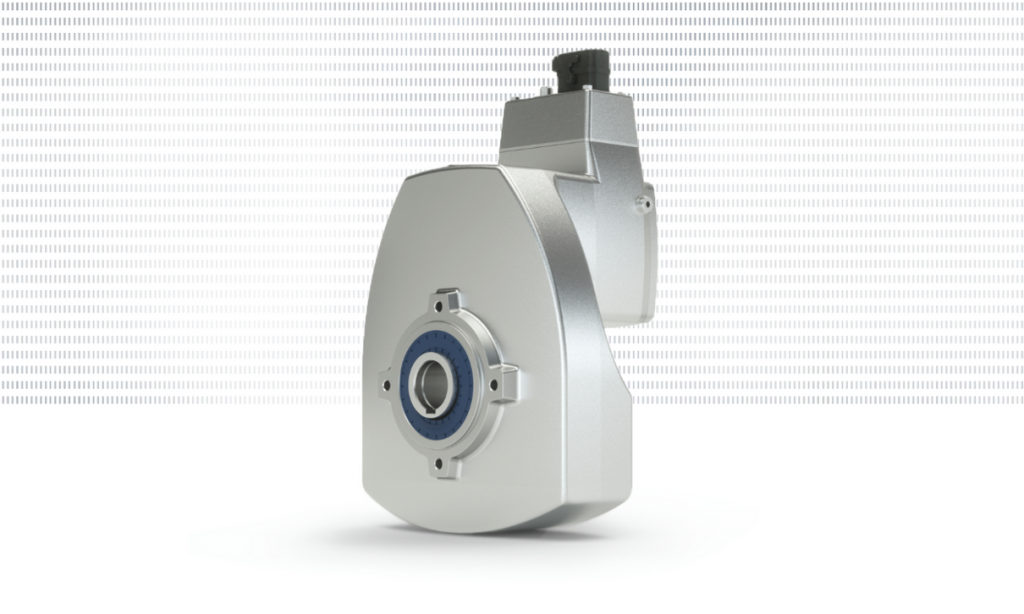

Duo Drive - Integrated Geared Motor ConceptDuo Drive - Integrated Geared Motor Concept

Nord Inline Helical Gearbox & Helical Geared Motor

Our Inline Helical Gearbox and Helical Geared Motor from Nord Drivesystems are engineered for high efficiency, smooth operation, and durability, making them ideal for applications in conveyor systems, food processing machines, packaging, and industrial automation. Designed to deliver maximum torque transmission with minimal energy loss, these solutions ensure low-noise, long-lasting performance in demanding environments.

Features

- Performance: 0.12 kW - 160 kW

- Torque range: 10 Nm - 26,000 Nm

- Sizes: 11

- Mounting position: M1, M2, M3, M4, M5, M6

Versions

- Solid shaft gear units

- Foot- or flange-mounted

- Coaxial gear units

Characteristics

- High efficiency for low operating costs

- Compact design means low space requirements

- Robust grey cast iron housing

- High axial and radial load capacities enable safe operation

- Quiet running

- Application-specific versions

Nord Parallel Shaft Helical Gearbox – Nord Parallel Helical Geared Motor

Product Description

Our Parallel Shaft Helical Gearbox from Nord Drivesystems is designed for applications requiring high torque, compact design, and reliable performance. Suitable for material handling, extrusion processes, Hoist, Long Travel, Cross Travel and rolling mills, this gearbox is built to handle high radial and axial loads with maximum efficiency. The parallel shaft design improves alignment, ensuring optimal performance with reduced downtime.

Features

- Performance: 0.12 kW - 200 kW

- Torque range: 110 Nm - 100,000 Nm

- Sizes: 15

- Mounting position: M1, M2, M3, M4, M5, M6

Versions

- Solid and hollow shaft (key, GRIPMAXX™, shrink disc)

- Bolt-on-, flange- and foot-mounted version and CEMA screw conveyor version

- Parallel shaft gear units

Characteristics

- Slim design for space-saving installation

- Robust grey cast iron housing

- High efficiency for low operating costs

- Various bearing concepts guarantee high axial and radial load capacities

- Quiet running

- Robust design for long life and easy maintenance

- Optional: Drywell version for mixers and agitators

- Application-specific versions

- Cheap to run thanks to low maintenance

Nord Bevel Helical Gearbox & Helical Bevel Gearbox for Industrial Use

The Bevel Helical Gearbox and Unicase Bevel Geared Motor from Nord Drivesystems provide a compact and durable solution for high-torque power transmission. Designed for industries like steel, mining, and cement, the Bevel Helical Gearbox offers smooth, efficient operation with minimal maintenance. The Unicase Bevel Geared Motor integrates the motor and gearbox into a single unit, featuring spiral bevel gears for quieter operation and reliable performance. Ideal for material handling, automation, and marine applications, these solutions offer customizable torque capacities and motor configurations.

Features

- Performance: 0.12 kW - 200 kW

- Torque range: 180 Nm - 50,000 Nm

- Sizes: 11

Versions

- Solid and hollow shaft (key, GRIPMAXX™, shrink disc)

- Bolt-on-, flange- and foot-mounted versions

- Angled gear units

Characteristics

- High efficiency for low operating costs

- Robust design for long life and easy maintenance

- Cheap to run thanks to low maintenance

- Robust grey cast iron housing

- Various bearing concepts guarantee high axial and radial load capacities

- Application-specific versions

Nord Bevel Helical Geared Motor

A bevel helical geared motor is a type of gear motor that combines the features of bevel and helical gears to transmit power. This type of geared motor is designed to provide high torque and efficiency, as well as a compact and durable solution for power transmission applications.

The bevel gears in a bevel helical geared motor are arranged at an angle to the input and output shafts, allowing for power transmission at a right angle. The helical gears in the gearbox are cut at an angle to the axis of rotation, providing smoother and quieter operation compared to spur gears. The combination of bevel and helical gears allows for high torque capacity and efficiency, making bevel helical geared motors ideal for applications where high performance is required.

Bevel helical geared motors are commonly used in applications such as conveyor systems, mixers, and packaging machines. They are also used in automotive, aerospace, and marine applications for power transmission.

These geared motors are available in a wide range of sizes and torque capacities, and can be configured with different ratios to meet specific application requirements. They can also be equipped with different types of motors, such as AC or DC motors, to provide the necessary power for the application.

Features

- Performance: 0.12 kW - 9.2 kW

- Torque range: 50 Nm - 660 Nm

- Sizes: 6

Versions

- Solid and hollow shafts (key, GRIPMAXX™, shrink disc)

- Standard version: SK 92.1: Foot/B14 flange with optional B5 flange and torque support. SK 93.1: B14 flange with optional B5 flange and foot mounting

- Angled gear units

Characteristics

- Aluminium housing version for low weight

- High efficiency for low operating costs

- Innovative design enables rapid cleaning and reduced weight

- High axial and radial load capacities enable safe operation

- Quiet running

- Large speed range

- nsd tupH version possible

- Application-specific versions

Nord Maxxdrive Right-Angle Gear Units

Maxxdrive is a brand of right-angle gear units produced by the German company, NORD Drivesystems. Maxxdrive gear units are designed for high torque applications and are used in a variety of industries, including food and beverage, mining, and material handling.

The Maxxdrive right-angle gear units feature a compact and durable design that allows them to operate in harsh environments. They are available in a range of sizes and torque capacities, with ratios up to 282:1. The gear units are also designed with an optimized housing that provides high power density, making them ideal for applications where space is limited.

Maxxdrive gear units feature a modular design that allows for easy maintenance and repair. They also come equipped with several advanced features, such as a shaft-mounted brake system, oil level and temperature monitoring, and an integrated thrust bearing. The gear units can also be equipped with various options, such as cooling systems and auxiliary drives, to meet specific application requirements.

Maxxdrive gear units are known for their high efficiency, which is achieved through the use of optimized gear geometries and a low-friction bearing design. They are also designed to provide quiet operation, even at high speeds and under heavy loads.

Features

- Performance: 1.5 - 2,150 kW

- Torque range: 15,000 - 260,000 Nm

- High strength precision-made one-piece housing

- Modular and flexible design for optimum adaptation to your application

- Low running noise

- Sizes: 11

- Mounting position: M1, M2, M3, M4, M5, M6

- Ratio: 12.5:1 - 30,000:1

Versions

- Various output shaft bearings for optimum adaptation to the application

- Effective cooling options available

- Wide range of possible motor attachments

- Supply of ready-to-install complete systems with coupling, brakes, monitoring, etc. is possible

- Modularly attached back stops enable easy access

Characteristics

- Optimum sealing enables long deployment times without leakage

- Low noise emission due to high precision bevel gears

- Effective fan cooling through optimised fan and air flow

- High torque capacity

- Increased lubricant life minimises maintenance costs

- Symmetrical design

- Mirror-image and inclined installation possible

- Optimal integration into the customer application through six possible installation positions

- Input and output shafts can be adapted to customers' dimensions

- Great reliability

- Long service life

- High precision

Nord Maxxdrive Parallel Gear Units

Maxxdrive is a brand of parallel gear units produced by the German company, NORD Drivesystems. Maxxdrive parallel gear units are designed for high torque applications and are used in a variety of industries, including food and beverage, mining, and material handling.

The Maxxdrive parallel gear units feature a robust and efficient design that allows them to operate in harsh environments. They are available in a range of sizes and torque capacities, with ratios up to 55:1. The gear units are also designed with a high power density, making them ideal for applications where space is limited.

Maxxdrive parallel gear units feature a modular design that allows for easy maintenance and repair. They also come equipped with several advanced features, such as a shaft-mounted brake system, oil level and temperature monitoring, and an integrated thrust bearing. The gear units can also be equipped with various options, such as cooling systems and auxiliary drives, to meet specific application requirements.

Maxxdrive gear units are known for their high efficiency, which is achieved through the use of optimized gear geometries and a low-friction bearing design. They are also designed to provide quiet operation, even at high speeds and under heavy loads.

Maxxdrive parallel gear units can be combined with various motors, including AC and DC motors, to provide the necessary power for the application. They can also be equipped with a wide range of accessories, such as couplings and adaptors, to provide a complete power transmission solution.

Features

- Performance: 1.5 - 6,000 kW

- Torque range: 15,000 - 282,000 Nm

- High strength precision-made one-piece housing

- Modular and flexible design for optimum adaptation to your application

- Low running noise

- Sizes: 11

- Mounting position: M1, M2, M3, M4, M5, M6

- Ratio: 5.6:1 - 30,000:1

Versions

- Various output shaft bearings for optimum adaptation to the application

- Many output flange options

- Wide range of possible motor attachments

- Effective cooling options available

- Supply of ready-to-install complete systems with coupling, brakes, monitoring, etc. is possible

Characteristics

- Optimum sealing protects against lubricant leakage

- Low noise operation reduces noise nuisance

- High torque capacity

- Increased lubricant life minimises maintenance costs

- Symmetrical design

- Mirror-image and inclined installation possible

- Optimal integration into the customer application through six possible installation positions

- Same housing size and installation dimensions for all speed ratios (two- and three-stage)

- Input and output shafts can be adapted to customers' dimensions

- Great reliability

- Long service life

- High precision

Nord Worm Geared Motor

A worm geared motor is a type of gear motor that uses a worm gear to transmit power between the motor and the output shaft. The worm gear consists of a screw-like gear (the worm) that meshes with a spur gear (the worm wheel). This arrangement provides a compact and efficient way to transmit power at a right angle.

Worm geared motors are commonly used in applications where high reduction ratios are required, such as conveyor systems, packaging machines, and material handling equipment. They are also used in automotive, agricultural, and industrial applications.

One advantage of worm geared motors is their ability to provide high reduction ratios in a single stage, which eliminates the need for multiple gear stages. This reduces the size and complexity of the gear system, making it more compact and easier to maintain.

Another advantage of worm geared motors is their ability to provide self-locking, which means that the gear system will not reverse drive if the load is greater than the output torque. This makes them ideal for applications where safety and stability are important.

Worm geared motors are available in a wide range of sizes and torque capacities, and can be configured with different ratios to meet specific application requirements. They can also be equipped with different types of motors, such as AC or DC motors, to provide the necessary power for the application.

Features

- Performance: 0,12 kW - 15 kW

- Torque range: 93 Nm - 3.058 Nm

- Sizes: 6

Versions

- Hollow and solid shaft gear units

- Bolt-on-, flange- and foot-mounted versions

- Angled gear units

Characteristics

- Soft and quiet running

- High overload capacity

- Robust design for long life and easy maintenance

- High axial and radial load capacities enable safe operation

- Robust grey cast iron housing

- Application-specific versions

Nord Universal SI Worm Geared Motor

A worm geared motor is a type of gear motor that uses a worm gear to transmit power between the motor and the output shaft. The worm gear consists of a screw-like gear (the worm) that meshes with a spur gear (the worm wheel). This arrangement provides a compact and efficient way to transmit power at a right angle.

Worm geared motors are commonly used in applications where high reduction ratios are required, such as conveyor systems, packaging machines, and material handling equipment. They are also used in automotive, agricultural, and industrial applications.

One advantage of worm geared motors is their ability to provide high reduction ratios in a single stage, which eliminates the need for multiple gear stages. This reduces the size and complexity of the gear system, making it more compact and easier to maintain.

Another advantage of worm geared motors is their ability to provide self-locking, which means that the gear system will not reverse drive if the load is greater than the output torque. This makes them ideal for applications where safety and stability are important.

Worm geared motors are available in a wide range of sizes and torque capacities, and can be configured with different ratios to meet specific application requirements. They can also be equipped with different types of motors, such as AC or DC motors, to provide the necessary power for the application.

Features

- Performance: 0.12 kW - 4.0 kW

- Torque range: 93 Nm - 3.058 Nm

- Sizes: 6

Versions

- Hollow and solid shaft gear units

- Bolt-on-, flange- and foot-mounted versions

- Angled gear units

Characteristics

- High overload capacity

- Application-specific versions

- Soft and quiet running

- Aluminium housing version for low weight

- Optional 10:1 helical pre-stage and double worm gear unit

- Modular, flexible and versatile application

- nsd tupH version possible

- Output shaft bearing for high load capacities

Nord Universal SMI Worm Geared Motor

The Universal SI Worm Geared Motor is a type of worm geared motor manufactured by Bonfiglioli, an Italian company specializing in power transmission and control solutions.

The Universal SI Worm Geared Motor is designed for a wide range of industrial applications, including conveyors, material handling equipment, and mixers. It features a compact and robust design, with a cast iron housing that provides high strength and durability. The worm gear is made of high-quality bronze, which ensures a long service life and high efficiency.

The Universal SI Worm Geared Motor is available in a range of sizes and torque capacities, with ratios up to 750:1. It can also be equipped with various accessories, such as brakes, torque limiters, and encoders, to meet specific application requirements.

One of the advantages of the Universal SI Worm Geared Motor is its high efficiency, which is achieved through the use of advanced gear geometries and low-friction bearings. This results in lower energy consumption and reduced operating costs.

The Universal SI Worm Geared Motor is also designed for easy maintenance, with a modular design that allows for quick and easy replacement of components. It also features a flexible mounting system, which allows for easy integration with a wide range of equipment.

Overall, the Universal SI Worm Geared Motor is a reliable and cost-effective solution for industrial power transmission applications that require high torque and efficiency.

Features

- Performance: 0.12 kW - 4.0 kW

- Torque range: 21 Nm - 427 Nm

- Sizes: 5

Versions

- Hollow and solid shaft gear units

- Bolt-on-, flange- and foot-mounted versions

- Angled gear units

Characteristics

- High overload capacity

- Application-specific versions

- Soft and quiet running

- Aluminium housing version for low weight

- Modular, flexible and versatile application

- Smooth housing surface for wash-down applications

- nsd tupH version possible

- Application-specific versions

Nord Duo Drive - Integrated Geared Motor Concept

The Duo Drive is an integrated geared motor concept developed by the German company SEW-Eurodrive. It combines a gear unit and a motor into a single compact unit, providing a high degree of efficiency, reliability, and flexibility.

The Duo Drive concept offers a range of benefits, including:

- Space-saving design: The compact design of the Duo Drive makes it ideal for applications where space is limited. By integrating the motor and gear unit, the overall size of the unit is reduced, allowing for more efficient use of space.

- High efficiency: The Duo Drive offers high efficiency levels, with low energy consumption and minimal power losses. This is achieved through the use of high-quality gear units and motors, as well as advanced control and monitoring systems.

- Flexibility: The Duo Drive concept offers a high degree of flexibility, with a range of options for motor and gear unit selection. This allows for customization of the unit to suit specific application requirements.

- Reliability: The Duo Drive is designed for high reliability and durability, with high-quality components and materials used throughout. It also features advanced monitoring and diagnostic systems, which help to detect and prevent potential issues before they occur.

- Easy installation and maintenance: The integrated design of the Duo Drive makes it easy to install and maintain. It also features a range of innovative features, such as quick-change components and plug-in connectors, which simplify the maintenance process.

Features

- Power range: 0.35–3.0 kW

- Extremely high system efficiency

- Compact wash-down design

- Maintenance reduction

- System solution for simple commissioning and plug & play

Versions

- Plug & play solution for fast commissioning

- Hygienic design

- Flexible attachment options: B5 flange, B14 flange

Characteristics

- Compact installation volume and thus space-saving

- High power density

- Quiet running through very low noise emissions

- Fewer wearing parts result in less maintenance

Why Choose Our Gearboxes?

- Premium quality gearboxes from top brands like Nord Drivesystems.

- Tailored solutions for diverse industrial applications like material handling, crushers, mills, and conveyors, Reactors, Agitators, Industrial Mixers, Ball Mills, Furnace, Ovens, Bucket Elevators, Cranes.

- Competitive pricing with superior performance and reliability.

- Expert consultation to help you select the right gearbox tailored to your requirements.