-

HGNHGN

-

HGSXHGSX

-

RDRNRDRN

-

RDRX , RDRBRDRX , RDRB

-

RDMNSRDMNS

-

Molasses PumpsMolasses Pumps

-

Bitumen PumpsBitumen Pumps

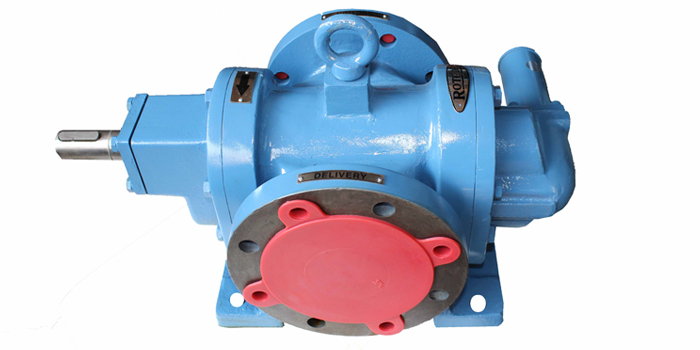

Rotary Gear Pumps

Rotary gear pumps are a type of positive displacement pump that are widely used in various industries for transferring fluids such as oils, fuels, and chemicals. These pumps are known for their high efficiency, smooth operation, and ability to handle a wide range of viscosities. In this article, we will discuss the working principle, types, and applications of rotary gear pumps.

Working Principle:

The working principle of a rotary gear pump is based on the meshing of two gears rotating in opposite directions. The fluid enters the pump through the inlet and fills the spaces between the gear teeth. As the gears rotate, the fluid is carried along the outer periphery of the gears and is discharged through the outlet. The tight tolerances between the gears and the pump casing prevent any leakage and ensure a constant flow of fluid.

Types of Rotary Gear Pumps:

There are two main types of rotary gear pumps: external gear pumps and internal gear pumps.

External Gear Pumps:

External gear pumps have two identical gears that rotate in opposite directions. The fluid is drawn into the pump between the teeth of the gears and is carried around the outside of the gears to the discharge port. External gear pumps are commonly used for low to medium viscosity fluids.

Internal Gear Pumps:

Internal gear pumps have one external gear and one internal gear. The fluid enters the pump through the inlet and is trapped between the external gear and the internal gear. As the gears rotate, the fluid is carried along the outer periphery of the internal gear and is discharged through the outlet. Internal gear pumps are commonly used for high viscosity fluids.

Applications of Rotary Gear Pumps:

Rotary gear pumps are used in a wide range of applications such as:

Chemical processing: Rotary gear pumps are commonly used for transferring chemicals such as acids, solvents, and resins.

Oil and gas industry: Rotary gear pumps are used for transferring oils, fuels, and lubricants in the oil and gas industry.

Food and beverage industry: Rotary gear pumps are used for transferring fluids such as fruit juices, beer, and wine in the food and beverage industry.

Transportation industry: Rotary gear pumps are used for transferring fluids such as diesel and gasoline in vehicles.

Conclusion:

Rotary gear pumps are an efficient and reliable option for fluid transfer in various industries. They come in different material of constructions such as CI, CS, SS to suit different fluid viscosities and Ph. Values. External gear pump are known for their smooth and quiet operation. Whether you need to transfer low viscosity fluids or high viscosity fluids, a rotary gear pump can be a great choice for your application.

Rotodel HGN Series Rotary Gear Pump

Rotary Gear Pumps (HGN) are positive displacement pumps that use two or more rotating gears to move fluid. These pumps are commonly used for the transfer of viscous liquids, such as oils, fuels, and chemicals.

The HGN pump consists of two gears, an idler gear, and a drive gear. The idler gear rotates on a pin fixed to the pump housing, while the drive gear is driven by a motor or other power source. The gears mesh together, and as they rotate, they create a suction force that draws fluid into the pump. The fluid is then trapped between the gear teeth and the pump housing, and as the gears continue to rotate, the fluid is forced out of the pump discharge.

HGN rotary gear pumps are known for their ability to handle a wide range of fluids, including abrasive and corrosive materials. They are also popular because of their high efficiency and low maintenance requirements. Additionally, HGN pumps are capable of producing high pressures, making them suitable for applications that require high flow rates and high pressure.

Overall, HGN rotary gear pumps are a reliable and cost-effective solution for fluid transfer in a variety of industries, including chemical, oil and gas, and manufacturing.

Features :

- Size from 1/2" to 3" BSP, Capacity from 20 LPM to 500 LPM max, Working Pressure 11KG/CM2, Temp 90°C Viscocity, 10,000 CST

- Compact

- Low Noise

- Efficient

- Easy Maintainable

- Cost Economical

Applications :

- 'ROTODEL' Rotary gear pumps are useful for handling viscouse liquids i.e.all kind of oils, vicouse chemicals,and food application. Following liquid can be handle with them.

- All kind of mineral oils.

- All kind of vegetable oils.

- Coal tar, Bitumen, asphalts

- Paints & varnish

- Sugar molasses & syrups

- Printing inks & Dyes.

- All kind of fish & animal oils.

- Glycerine & glycole.

- Fuel oil, Diesel oil & funace oil

- Soap solution & lard.

- Glue.

- Viscouse chemicals.

- Rotary gear pumps finds wide application in Power Plant, Steel Mills, Refineries, Oil Storage Instolation etc. Design improvement is a continous process at DEL there for information in this catalouge is subject to change without notice.

Rotodel HGSX Series Rotary Gear Pump

Rotary Gear Pumps (HGSX) are positive displacement pumps that use two or more rotating gears to transfer fluids. These pumps are widely used for pumping viscous liquids such as oils, fuels, chemicals, and other fluids that require a constant flow rate.

The HGSX pump consists of two or more gears, with one gear acting as the driver gear and the others as driven gears. As the driver gear rotates, it drives the driven gears, which in turn rotate, drawing fluid into the pump. The fluid is then trapped between the gear teeth and the pump housing, and as the gears continue to rotate, the fluid is discharged from the pump.

HGSX rotary gear pumps are popular because of their ability to handle a wide range of fluids, including abrasive and corrosive materials. They are also known for their high efficiency, low maintenance requirements, and ability to produce high pressures.

The HGSX rotary gear pump is commonly used in various industries, including chemical processing, oil and gas, food and beverage, and other industrial applications. The pump’s versatility and reliability make it a popular choice for applications requiring constant flow rates and high-pressure output. Overall, HGSX rotary gear pumps are a reliable and cost-effective solution for fluid transfer applications.

Features :

- For handling corrosive, abbrasive, hygienic viscous liquid for transfer, loading-unloading & pressurising applications.

- Compact

- Efficient

- Reliable

- Easy Maintainable

- Easy Cleanable

Specifications :

- 'ROTODEL' Rotary gear pumps are useful for handling viscouse liquids i.e.all kind of oils, vicouse chemicals,and food application. Following liquid can be handle with them.

- Pump Body

- Front Cover

- Back Cover

- Seal Cover - SS 316 - CF8M

- R.H. & L.H. Gear

- Rotor/Stator Shaft

- Dom nuts, Stud & Key - SS AISI 316

- Bearings - Teflon Coated 'DU'

- Bracket - CI/CS

- Sealing & Packing - Teflon

Uses :

- This compact & efficient SS pumps finds different application for handling food products like Ghee, Butter fruit pulp, vegetable souse, kanji etc. They are also used in Pharmaceutical application for handling sugar solution, Glycerine, Glycol etc. Corrosive viscous chemicals application can also be met with this pump most effectively.

Rotodel RDRN Series Rotary Gear Pump

Rotary Gear Pumps (RDRN) are positive displacement pumps that use a pair of meshing gears to move fluid. These pumps are typically used for pumping low to medium viscosity liquids, including oils, solvents, and other industrial fluids.

The RDRN rotary gear pump consists of two gears that mesh together, one driven by a motor or other power source, and the other driven by the first gear. As the gears rotate, the fluid is drawn into the pump and trapped between the gear teeth and the pump housing. The fluid is then displaced and discharged from the pump as the gears continue to rotate.

RDRN rotary gear pumps are known for their high efficiency and ability to maintain a consistent flow rate, even with varying fluid viscosities. They are also capable of generating high pressures, making them suitable for a wide range of applications.

The RDRN pump is commonly used in industries such as chemical processing, oil and gas, and food and beverage. They are popular for their reliability, low maintenance requirements, and ability to handle a variety of fluids. Overall, RDRN rotary gear pumps are a reliable and cost-effective solution for fluid transfer applications.

Overview :

- From 1/2. to 6" NB Size (Flanged to ASA 150 Class)Capacity, From 0.5 TO 200 WTI, Pres-up to 11 Kaden, Viscosity up to 1,00,000 - est, temperature - up to 110110ºC

- Compact

- Economical

- Low Noise

Advantages

- 'ROTODEL' Rotary gear pumps are useful for handling viscouse liquids i.e.all kind of oils, vicouse chemicals,and food application. Following liquid can be handle with them.

- Herrigbone rotos design eliminates side thruts.

- Modified tooth profile enhances the tooth life.

- Floating gear-design ensures uniform load distribution.

- Low-leakage path by design improve volumetric efficiency.

- Extra thick shaft reduces bending effectively.

- Sleeve on shaft make maintenance economical & easy.

Pump Motor Coding

- Sign # Indicates Pump Size - 5-short, 6-medium, 7-long

- Sign @ Indicates Pump Type - 0-RDRB, 1-RDRBJ, 2-RDRN, 3-RDRNJ, 4-RDRX, 5-RDRXJ

- Sign * Indicates Motor Type - W-NON-Flame Proof, X-Flame proof motor

Rotodel RDRX , RDRB Series Rotary Gear Pump

Rotary Gear Pumps (RDRX) are positive displacement pumps that use a pair of meshing gears to transfer fluid. These pumps are typically used for pumping low to medium viscosity liquids, including oils, fuels, solvents, and other industrial fluids.

The RDRX rotary gear pump is similar to other gear pumps in design, consisting of two gears that mesh together and rotate in opposite directions. As the gears rotate, they create a suction force that draws fluid into the pump. The fluid is then trapped between the gear teeth and the pump housing and is displaced as the gears continue to rotate.

The RDRB rotary gear pump consists of two gears that mesh together and rotate in opposite directions. As the gears rotate, they create a suction force that draws fluid into the pump. The fluid is then trapped between the gear teeth and the pump housing and is displaced as the gears continue to rotate.

RDRB rotary gear pumps are known for their high efficiency and ability to maintain a consistent flow rate, even with varying fluid viscosities. They are also capable of generating high pressures, making them suitable for a wide range of applications.

The RDRB pump is commonly used in industries such as chemical processing, oil and gas, and food and beverage. They are popular for their reliability, low maintenance requirements, and ability to handle a variety of fluids.

Advantages

- Herrigbone rotos design eliminates side thruts.

- Modified tooth profile enhances the tooth life.

- Floating gear-design ensures uniform load distribution.

- Low-leakage path by design improve volumetric efficiency.

- Extra thick shaft reduces bending effectively.

- Sleeve on shaft make maintenance economical & easy.

Uses :

- RDMNS Pumps are used for handling thinner liquid at moderate pressurizing viz. foam pressurizing application for fire fighting, high pressure coolant transfer application for machine tools, light fuel pressurizing application or boiler & burners, heavy viscous liquid transfer application such as Molasses, Magma, Soap stock, Tar, Bitumen, Paints, Varnish, Crude oil etc.

Rotodel RDMNS Series Rotary Gear Pump

Overview :

- Compact

- Efficient

- Durable

Features :

- Pump Body CF8

- Front Cover CF8

- Back Cover CF8

- Gland Cover CF8

- Rotar Gear SS-316

- Stator Gear SS-316

- Rotar Shaft EN-57/SS-430

- Stator Shaft EN-57/SS-430

- W.Plate - Bronze/Graphite

- Bushes Teflon Coated DU

- Shaft Seal - Z Pack/Mech. Seal

- Key SS-316

Uses :

- RDMNS Pumps are used for handling thinner liquid at moderate pressurizing viz. foam pressurizing application for fire fighting, high pressure coolant transfer application for machine tools, light fuel pressurizing application or boiler & burners, heavy viscous liquid transfer application such as Molasses, Magma, Soap stock, Tar, Bitumen, Paints, Varnish, Crude oil etc.

Rotodel Molasses Pumps

Molasses pumps are positive displacement pumps that are specifically designed for the transfer of molasses, a thick, viscous, and sticky by-product of sugar production. Molasses pumps are commonly used in the sugar industry for the transfer of molasses from storage tanks to various processing equipment or transportation vehicles.

Due to the high viscosity of molasses, molasses pumps are typically designed with large, wide channels and slow rotating speeds to prevent clogging and ensure smooth and efficient transfer. They may also have features such as high torque motors, heavy-duty gearboxes, and specially designed rotors to handle the thick and sticky consistency of molasses.

Molasses pumps can be made from a variety of materials depending on the specific application, including cast iron, stainless steel, and various types of polymers. They may also be equipped with various safety features such as overpressure relief valves and automatic shut-off systems to prevent damage or accidents during operation.

Rotodel Bitumen Pumps

Bitumen pumps are positive displacement pumps designed to handle and transfer bitumen, a thick and highly viscous liquid used in various industries such as road construction, roofing, and waterproofing. Bitumen pumps are designed to operate at high temperatures and are typically used to transfer bitumen from storage tanks to application equipment such as sprayers, spreaders, or rollers.

Bitumen pumps are typically classified as either rotary or reciprocating pumps. Rotary bitumen pumps are commonly used and consist of a pair of rotating gears or lobes that trap the bitumen between them and transfer it through the pump. Reciprocating bitumen pumps, on the other hand, use a piston or diaphragm to move the bitumen through the pump.

Bitumen pumps are usually constructed from materials that are able to withstand the high temperatures and corrosive nature of bitumen, such as cast iron, steel, or stainless steel. They may also include features such as heating jackets or external heaters to keep the bitumen at a consistent temperature, and strainers or filters to prevent clogs or damage to the pump. Additionally, safety features such as relief valves or automatic shut-off systems may also be included to ensure safe and efficient operation.

Overview :

- We emerged as most prominent and leading Bitumen Pump manufacturers in India. We offer ROTODEL gear pump type "HGSX" is all stainless steel SS-316 self-priming, bi-directional positive displacement rotary pump, fitted with teflon coated dry running 'DU' bush bearing. Three-piece design makes the pump easy cleanable, easy maintainable simply by removing four dom nuts on back cover. The raw materials used in manufacturing of product are of high quality. Our skilled professionals by using latest technologies bring about the production of Bitumen Pumps. All these products passed through the highest level of quality check to ensure the 100% accuracy. As an authentic Bitumen pump supplier in Gujarat, we provide Bitumen pump for Bitumen Transfer in Road Plants Which is Easily Replaceable and Cost Effective.