-

Water ApplicationWater Application

-

Pulp And Paper Stock PumpPulp And Paper Stock Pump

-

Chemical ApplicationChemical Application

-

ANSI Chemical Process ANSI Chemical Process

-

Vertical Sump PumpsVertical Sump Pumps

-

Horizontal Spilt CasiingHorizontal Spilt Casiing

-

Horizontal Multi Stage PumpsHorizontal Multi Stage Pumps

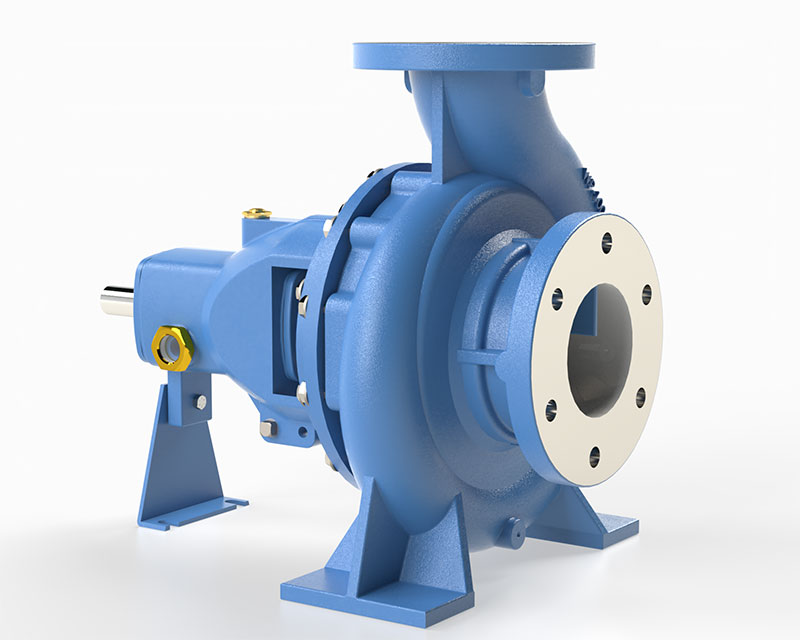

Water Application

A water application pump is a device that is used to move water from one location to another. These pumps can be used in a variety of applications, such as irrigation, drainage, and water transfer.

There are many types of water application pumps, including centrifugal pumps, submersible pumps, and diaphragm pumps. Each type of pump has its own unique set of advantages and disadvantages, so it’s important to choose the right type of pump for your specific needs.

Centrifugal pumps are the most common type of water application pump, and they work by using an impeller to create a flow of water. Submersible pumps are designed to be submerged in water, and they are often used in deep wells or other applications where the water source is below ground level. Diaphragm pumps use a flexible diaphragm to move water, and they are often used in applications where a high level of accuracy is required.

When choosing a water application pump, it’s important to consider factors such as flow rate, pressure, and power consumption. You should also consider the type of water you will be pumping, as certain types of pumps are better suited for handling specific types of water. Finally, you should consider the overall durability and reliability of the pump, as well as the level of maintenance required to keep it running smoothly over time.

WP Series

- Pump Delivery Size D DN 32 to DN 150

- Head H Up to 100 mtrs (328feet)

- Capacity Q Up to 550 m³/hr

- Max.Working Pressure 16 bar

- Max.Operating (Temp) Up to 100°C

- Speed N 2900/1450 rpm

Application :

- General water supply & Industrial water supply

- Agriculture and Irrigation

- Water treatment plants

- Paper & pulp industries

- Power plants

- De-salination

- HVAC & Firefighting system

- Sprinkler systems

- Sea water desalination plants

- Cooling Tower

- Cement and Process industries

- Food Processing & Textile

Pulp And Paper Stock Pump

A pulp and paper stock pump is a specialized type of pump used in the paper manufacturing process. These pumps are used to transport the pulp and paper stock mixture, which is a combination of wood chips and chemicals, from the pulp mill to the paper machine.

Pulp and paper stock pumps are typically centrifugal pumps, which means they use an impeller to create a flow of fluid. They are designed to handle high flow rates and high concentrations of solids, and they are typically made from materials that can withstand the abrasive nature of the pulp and paper stock mixture.

There are several types of pulp and paper stock pumps available, including horizontal pumps, vertical pumps, and split case pumps. Horizontal pumps are typically used in applications where space is limited, while vertical pumps are often used in applications where a high level of reliability is required. Split case pumps are designed to handle high flow rates and high pressures, and they are often used in large paper mills.

When selecting a pulp and paper stock pump, it’s important to consider factors such as the flow rate and pressure required, the type of pulp and paper stock mixture being transported, and the level of maintenance required to keep the pump running smoothly. It’s also important to select a pump that is compatible with the other equipment in the paper manufacturing process, such as the pulp mill and the paper machine.

PSX Series

- Pump Delivery Size D DN 65 to DN 400

- Head H Up to 80 mtrs (260 feet)

- Capacity Q Up to 2500 m³/hr

- Max.Working Pressure 22 bar

- Max.Operating (Temp) 140 °C

- Speed N 1450 rpm

Application :

- Paper Mills application like chest pump, refineries pump, Fan pump, Centri cleaner pump,

- Back water pump, separator pump, couch pit pump, turbo feed pump, stock pump

- Pulp making Process, Pulp Preparation Process and paper making Process

- Coating production, caustic Gasification, DE inking, Flocculation

- Paper Bleaching, Additives, Dyes Process

- Pulp slurry transfer- Cellulose fibre slurries, Evaporators, Concentrators applications

- Flash tanks, Flotation cells, Black liquor& waste Stock

- Acid , alkaline, corrosive slurries etc

- Heavily contaminated liquids, raw sewage, sludge

- Absorption plant & Chemical Process Industries

- Agro and Fertilizer Plants

- Drugs and Pharmaceutical

- Liquor and Bewerages Plant

- Cements and Sugar Plants

- Textile, Jet Dyeing, Dyes & Intermediates

- Organic and Inorganic Liquids Refineries

- Effluent Treatment Plants

- Chlorinated water, Volatile Liquids

- Oil Extraction and Waste

- Slurry Handling

Chemical Application

A chemical application pump is a type of pump that is specifically designed to handle chemicals and other corrosive fluids. These pumps are used in a variety of industrial applications, including chemical processing, water treatment, and oil and gas production.

Chemical application pumps can be divided into two main categories: positive displacement pumps and centrifugal pumps. Positive displacement pumps are designed to move a specific volume of fluid per stroke or revolution, while centrifugal pumps use an impeller to create a flow of fluid.

When selecting a chemical application pump, it’s important to consider factors such as the type of chemical being pumped, the flow rate and pressure required, and the level of maintenance required to keep the pump running smoothly. Some chemicals may require the use of a specific type of pump material, such as stainless steel or plastic, to prevent corrosion or chemical reaction with the pump components.

Other important considerations when selecting a chemical application pump include the temperature and viscosity of the fluid being pumped, as well as the potential for abrasion or erosion of the pump components. It’s also important to select a pump that is compatible with the other equipment in the chemical processing system, such as pipes, valves, and fittings.

KCP Series

- Pump Delivery Size D DN 32 to DN 200

- Head H Up to 140 mtrs (460feet)

- Capacity Q Up to 900 m³/hr

- Max.Working Pressure 22 bar

- Max.Operating (Temp) 500°C

Application :

- Chemical Process Industries

- General Refinery Services, Oil Extraction and Waste

- Pulp and Paper

- Erosive/Corrosive Liquors & Volatile Liquids

- hydrocarbon, oil, thermic fluids, Chemical & Process Transfer

- Demineralised Water, Cooling Tower, Hot Water

- clarified water, back water, white water, soft water & Condensates

- Fertilizer Plants

- Effluent Treatment Plants

- Textile, Jet Dyeing, Dyes & Intermediates

- Organic and Inorganic Liquids Refineries

- Sugar Plants, cement, power and steel

- Bulk Drugs and Pharmaceutical

- Heating and Air Conditioning Plants

- General Water Supply & Agriculture

- Fire Fighting

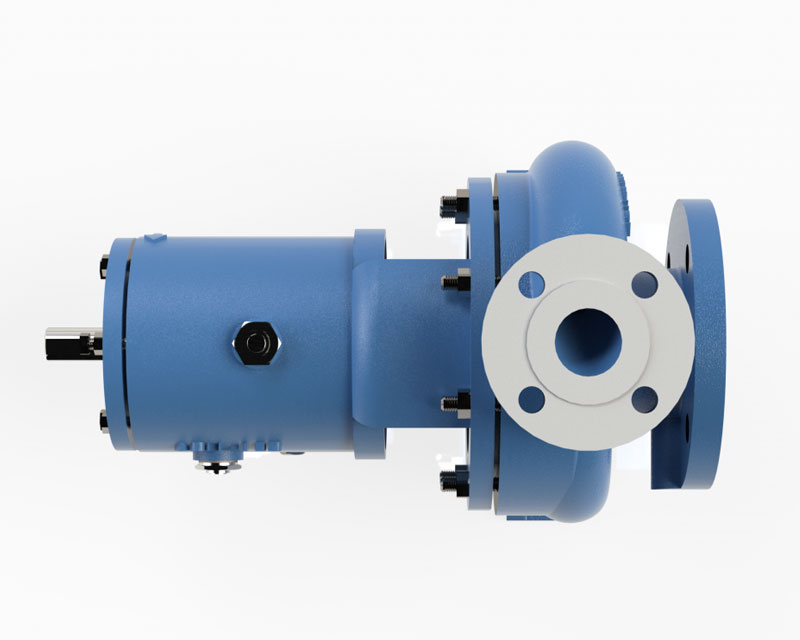

ANSI Chemical Process

ANSI Chemical Process pumps are a type of centrifugal pump that is designed specifically for use in chemical processing applications. These pumps are commonly used in industries such as oil and gas, chemical processing, and water treatment.

The ANSI Chemical Process pump is a standardized design that meets the American National Standards Institute (ANSI) B73.1 standard. This standard defines the dimensions and performance requirements for end-suction centrifugal pumps used in chemical processing applications. The ANSI standard ensures that the pumps are interchangeable between manufacturers, making it easier for users to select and maintain their pumps.

ANSI Chemical Process pumps are typically made from materials such as stainless steel, alloy 20, or hastelloy, which can withstand the corrosive and abrasive nature of the chemicals being processed. They are also designed with a back pull-out design, which allows for easy maintenance and repair of the pump without disturbing the piping system.

These pumps are available in a variety of configurations, including single-stage or multi-stage, with either a closed or open impeller. They can handle flow rates up to several thousand gallons per minute, and pressures up to several hundred pounds per square inch.

When selecting an ANSI Chemical Process pump, it’s important to consider factors such as the chemical being processed, the required flow rate and pressure, and the temperature and viscosity of the fluid. It’s also important to select a pump that is compatible with the other equipment in the chemical processing system, such as valves and piping.

ACH Series

- Pump Delivery Size D DN 25 to DN 100

- Head H Up to 180 mtrs (590feet)

- Capacity Q Up to 600 m³/hr

- Max.Operating (Temp) 200 °C

- Max.Working Pressure 24 bar

- Speed N 960/1450/2900 rpm at 50 Hz

- Speed N 1200/1750/3500 rpm at 60 Hz

Application :

- Acids, Brine, Fertilizer, Steel & mining, Pulp & paper, Chemicals, Power

- generation

- Slurry, Solvents, Textile, breweries, Jet dyeing,

- Grain processing, Sugar, Distilleries, Refineries, Food processing,

- Pharmaceuticals, Steel,

- Water treatment, oil & gas, Petrochemicals, Automotive, Oil Extraction and Waste,

- Cellulose, hypo, spent wash, starch handling, green liquor, black liquor

- Caustic slurry lime mud slurry, extraction, China clay, Effluent Treatment

- Plants

- Organic and Inorganic Liquids Refineries

Vertical Sump Pumps

Vertical sump pumps are a type of centrifugal pump that is designed to operate while submerged in a fluid, typically with the motor mounted on top of the pump. They are commonly used in industrial applications, such as in mining, power generation, and chemical processing, where fluids need to be pumped from underground or below-grade sources.

Vertical sump pumps are typically designed with a vertical shaft and an impeller that is suspended in the fluid being pumped. The motor is mounted on the top of the pump, and power is transmitted to the impeller through the vertical shaft. These pumps are available in a variety of configurations, including single-stage or multi-stage, with either a closed or open impeller.

One of the key benefits of vertical sump pumps is that they are designed to operate while completely submerged in the fluid being pumped. This helps to prevent cavitation and ensures that the pump is always primed and ready to operate. They also have a small footprint, which makes them ideal for use in applications where space is limited.

When selecting a vertical sump pump, it’s important to consider factors such as the required flow rate and pressure, the type of fluid being pumped, and the temperature and viscosity of the fluid. It’s also important to select a pump that is compatible with the other equipment in the pumping system, such as valves and piping. Additionally, it’s important to consider the level of maintenance required to keep the pump running smoothly over time.

KVO Series

- Pump Delivery Size D DN 25 to DN 300

- Head H Up to 100 mtrs (328 feet)

- Capacity Q Up to 1400 m³/hr

- Sump Depth Up to 3mtrs

- Max.Working Pressure 16 bar

- Max.Operating (Temp) 120 °C

- Speed N 1450/2900rpm

Application :

- Sump Drainage

- Hydrocarbon Processing

- Industrial Processes

- Salt, Pharmaceutical

- Automotive Solvents.

- Wet Pit

- Flood Control

- Air Wash Systems

- ETP, STP & Waste Water treatment plant.

- Acid Transfers

- Solvents, Diesel & Petrol Transfer.

- Light Slurries, Organic Chemical Processing.

- Water, Cooling Water, Effluent, Cleaning Product & Hydrocarbons.

- Zink & Copper Plant.

- Slurry transfer

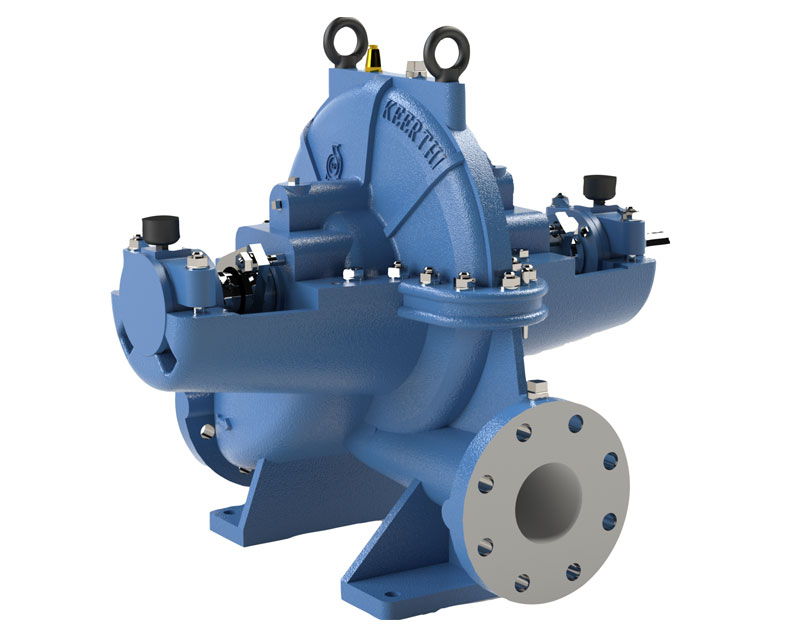

Horizontal Spilt Casing

Horizontal split casing refers to a type of pump casing that is split horizontally into two sections, with the impeller and shaft located in between. This design allows for easy access to the internal components of the pump without having to disconnect the piping, which can save time and reduce maintenance costs.

Horizontal split casing pumps are commonly used in applications where large volumes of liquid need to be moved, such as in water treatment plants, industrial processes, and municipal water supply systems. They are also used in oil and gas applications, including the transfer of crude oil, refined petroleum products, and natural gas liquids.

One advantage of the horizontal split casing design is that it allows for larger impellers and higher flow rates than other types of pumps. Additionally, the split casing design can help to reduce the risk of cavitation, which can occur when high-speed liquid flow creates areas of low pressure that can damage the impeller and other components of the pump.

Overall, horizontal split casing pumps are a popular choice for a wide range of applications due to their durability, ease of maintenance, and ability to handle large volumes of liquid with high efficiency.

HSC Series

- Pump Delivery Size D - DN 50 to DN 200

- Head H - Up to 120 mtrs (394 feet)

- Capacity Q - Up to 3500 m³/hr

- Max.Working Pressure - 16 bar

- Max.Operating (Temp) - 100 °C

- Speed N -1450 rpm

Application :

- General Water Supply

- Flood Irrigation & Sprinkler

- Public Water supply & Water treatment

- HVAC, Cooling tower & Condensate Water circulation

- Power industry utilities

- Storm water and drainage

- Sewage Disposal

- Swimming pool & amusement

- Various industrial applications

- Injection and Spray

- Boiler feed water

Horizontal Multi Stage Pumps

Horizontal multi-stage pumps are a type of centrifugal pump that consist of multiple impellers mounted on a common shaft and enclosed in a single casing. Each impeller is designed to add pressure to the fluid, with the discharge from one impeller feeding the suction of the next.

The multi-stage design allows for the pump to generate higher pressures than a single-stage pump, making it suitable for a variety of applications where high-pressure and high-head conditions are required, such as in water supply systems, industrial processes, and irrigation systems.

Horizontal multi-stage pumps can be designed with different materials of construction, including cast iron, stainless steel, and bronze, to suit different applications and operating conditions. They can also be designed with different types of impellers, such as closed, semi-open, or open impellers, depending on the fluid being pumped.

One advantage of horizontal multi-stage pumps is that they offer high efficiency and low operating costs compared to other types of pumps, such as positive displacement pumps. They also have a compact design, which can help to save space in installations where space is limited.

Overall, horizontal multi-stage pumps are a versatile and reliable choice for a wide range of applications, and their ability to handle high-pressure and high-head conditions makes them a popular choice in many industries.

Horizontal Multi Stage Pumps

- Pump Delivery Size D DN 80 to DN 100

- Head H Upto 540 mtrs ( 1771.7 feet)

- Capacity Q Up to 70 m³/hr

- Max.Working Pressure 54 bar

- Max.Operating (Temp) 180 °C

- Speed N 2900/1450 rpm

Application :

- Boiler feed, Pressure Booster

- High rise buildings

- Drinking water transfer

- HVAC, Hot & cold-water circulation

- Civil-water-supply General Water supply

- Irrigation &Water supply

- Fire fighting

- Swimming pool & amusement parks

- Various industrial applications

- Cooling tower

- Power industry utilities

- General Water Supply

- Water treatment plant